Contact us

- Home

- »

- Installation & Maintenance

- »

- Flawless LED Screen Installation Guide: Indoor, Outdoor & Rigging Steps

Flawless LED Screen Installation Guide: Indoor, Outdoor & Rigging Steps

Planning a professional LED screen setup and installation? Precision is everything.

Whether you are integrating a P1.8 video wall for a TV studio or erecting a massive P10 highway billboard, proper LED screen installation is the difference between a stunning display and a technical disaster. A poor installation leads to visible seams, signal blackouts, and potential safety hazards.

In this expert guide, UnifyLED goes beyond the basics. We cover the complete engineering workflow of LED video screen installation, including critical protocols for signal redundancy, structural wind loads, and precise seam calibration.

Table of Contents

Preparation: The Installation Checklist

Before the truck arrives, ensure you have the right gear. Professional LED screen installation requires precision.

Essential Tools:

Precision: Laser Level (Crucial for the first row), Multimeter.

Mounting: Impact drill, Allen keys (Hex keys), M10/M12 bolts.

Cabling: RJ45 crimping tool, CAT6 cables, Spare power connectors.

Safety: Hard hats, safety harnesses (for outdoor/heights).

Pro Tip: Always order 3-5% spare modules and cables. Electronics can fail, and having a spare on-site saves the event.

1. The Workflow: How to Install LED Screen Cabinets

Before we discuss specific scenarios, every integrator must master the standard workflow. It is not just about hanging boxes; it is about ensuring stability and connectivity

Step 1: Sub-Frame Precision

The steel structure is the skeleton. Ensure your horizontal beams align perfectly with the cabinet height.

Pro Standard: The frame tolerance must be within ±1mm. If the frame is crooked, no amount of cabinet adjustment can fix the gaps later.

Step 2: Cabinet Mounting

Always start installing from the Bottom-Center (for ground/wall) or Top-Center (for hanging). This ensures the screen is symmetrical. Use connection plates or Fast-Locks to pull cabinets together tightly.

Step 3: Wiring & Redundancy (The "Never-Black" Protocol)

This is where professionals differ from amateurs.

A standard LED screen setup and installation uses a simple “Daisy Chain.” But for critical events, you need Redundancy.Signal Loop Backup: Don’t just run a “Z” chain. Connect the output of the last cabinet back to the backup port of the processor. If the main cable is cut, the signal automatically reverses flow instantly.

Power Load Balancing: Ensure your 3-phase power (R/S/T) is perfectly balanced. If one phase carries 80% load and another 20%, you risk tripping the main breaker.

Step 4: Software Configuration

Use control software (Novastar/Brompton) to send the RCFG file.

Expert Tip: Always save the configuration file to each receiving card (Readback function). If a card is replaced later, it can automatically fetch the correct config.

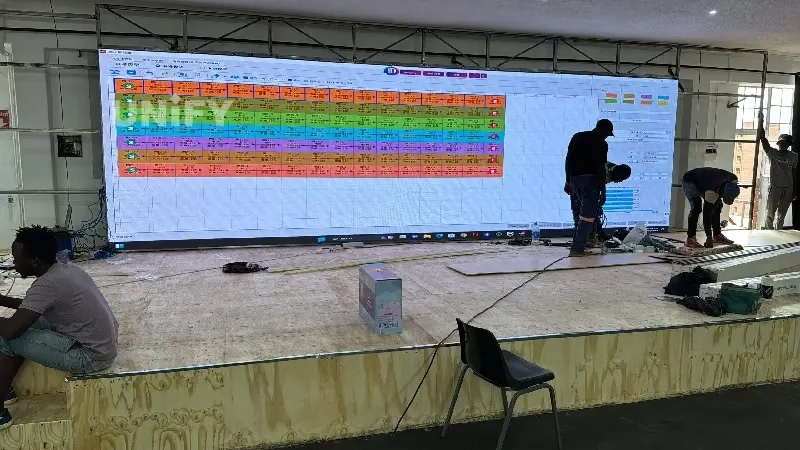

2. Scenario A: Indoor LED Screen Installation (Precision & Flatness)

For indoor LED screen installation (especially P2.5 and below), the challenge is the Z-Axis (Flatness). Viewers are close; a 0.5mm ridge looks like a black line.

Step 1: The Laser Level: Use a 360° laser level to ensure the bottom row is perfectly horizontal.

Step 2: The “Six-Axis” Adjustment: Mounting is just the start. Use the 6-axis adjustment mechanism (found on high-end die-cast cabinets) to micro-adjust the depth of each module corner.

Step 3: Seam Brightness Correction: After installation, you may still see faint grid lines. Use a Calibration Camera to perform “Chroma/Luma Calibration.” This digitally dims the bright edges to create a seamless, paper-like surface.

Recommended Product: Fine Pixel Pitch Indoor Series for seamless integration.

3. Scenario B: Outdoor LED Screen Installation (Heat & Wind)

Outdoor LED screen installation is an engineering battle against nature. It’s not just about waterproofing; it’s about Heat and Wind.

Step 1: Wind Load Calculation: A 100sqm screen acts like a giant sail. In coastal areas, your structure must withstand Hurricane Level 12 winds. Chemical anchors are insufficient; pre-embedded foundation bolts and reinforced H-beams are mandatory.

Step 2: Thermal Management: A screen running at 6000 nits generates massive heat. If the internal temperature exceeds 60°C, ICs will fail.

Requirement: For screens >20sqm, install temperature-controlled exhaust fans or AC units inside the maintenance catwalk.

Step 3: Waterproof Sealing: Beyond rubber rings, apply specific outdoor structural sealant (silicone) along the top row gaps to prevent rainwater from trickling behind the modules.

4. Scenario C: LED Screen Ceiling Installation (Rigging Safety)

Rigging is physically the easiest method but has the strictest safety protocols.

Step 1: The 5:1 Safety Factor: All motors, trusses, and shackles must be rated for 5 times the actual load. If your screen weighs 1 ton, your rigging points must handle 5 tons.

Step 2: Secondary Safety: Never rely solely on the motor hook. Always use Steel Safety Cables (Steels) wrapped around the truss and the screen header bar as a fail-safe.

Step 3: Vertical Cable Management: Use velcro or zip-ties to secure cables along the truss. Loose cables can block the cooling vents or look unprofessional in a led screen ceiling installation.

5. Critical Comparison: Wall Mount vs. Outdoor Fixed vs. Ceiling Rigging

Choosing the right installation method isn’t just about aesthetics; it dictates your budget, timeline, and safety requirements. Below is a detailed breakdown of the three most common installation scenarios.

The "Installation Triangle" Comparison Matrix

Feature | Indoor Wall Mount (Fixed) | Outdoor Column/Pole (Fixed) | Ceiling Rigging (Rental/Touring) |

Primary Application | Conference Rooms, Retail Stores, Churches | Highways, Billboards, Stadiums | Concerts, Exhibitions, TV Studios |

Structural Base | Existing Wall + 40mm Steel Grid | Concrete Foundation + Heavy Steel Columns | Aluminum Truss + Electric Motors |

Installation Difficulty | Moderate | Very High | Specialized |

Equipment Needed | Scaffolding, Laser Level, Drills | Crane, Excavator, Welding Machine | Chain Hoists, Slings, Shackles |

Waterproofing | Not Required | Critical (IP65/IP67) + Glue Sealing | Outdoor: Yes / Indoor: No |

Maintenance Access | Front Service (Magnetic Tool) | Rear Service (Catwalk/Door) | Rear Service (Climbing) |

Safety Risk | Low (Flatness is the main challenge) | High (Wind Load & Lightning) | High (Falling Hazard / Weight Load) |

Typical Timeframe | 2-3 Days (for 20sqm) | 7-15 Days (Inc. Foundation) | 2-4Hours (Rapid Deployment) |

In-Depth Analysis: Risks & Cost Factors

A. The Hidden Costs of Outdoor Installation

Many clients underestimate the Civil Engineering cost for outdoor screens. Unlike indoor screens that attach to existing walls, outdoor billboards often require:

Soil Analysis & Foundation: Digging deep and pouring concrete to support tons of steel.

Wind Load Calculation: The structure must withstand typhoon-level winds. This requires thicker steel and professional welding, often costing 15-20% more than the screen itself.

B. The Safety Criticality of Ceiling Rigging (Hanging)

Rigging looks the easiest (just hang it up?), but it has the strictly safety protocols.

Weight Limit: You must calculate the Total Hanging Weight (Screen + Cabling + Bars). A 50sqm screen can weigh over 1,500kg.

Safety Factor (5:1): All motors and trussing must be rated for at least 5 times the actual load to comply with western safety standards.

Secondary Safety: Always use safety steel cables (steels) as a backup in case the main motor hook fails.

C. Precision is King for Indoor Walls

For indoor P1.8 or P2.5 screens, the challenge is Flatness.

Because viewers are only 2 meters away, a 0.5mm gap looks like a black line.

Recommendation: For high-end indoor installations, consider using Die-Cast Aluminum Cabinets instead of simple iron cabinets. They are CNC-machined to be perfectly flat, reducing installation difficulty by 50%.

6. Troubleshooting: Common On-Site Failures

Even with a perfect LED screen setup and installation, issues happen. Here is how to fix them:

1. The “Crazy Flashing” Screen

Cause: Ground loops or EMI interference from stage audio/lights.

Fix: Use Shielded CAT6 (STP) cables. Ensure the screen’s grounding is separate from the audio system’s grounding.

2. The “Pink/Green” Block

Cause: A loose flat ribbon cable connecting the module to the hub card.

Fix: Power off, open the cabinet, and reseat the ribbon cable firmly.

3. Tripping Breakers on Startup

Cause: Inrush Current. LED screens draw 5x their operating current for a millisecond when turned on.

Fix: Do not use a standard switch. Install a PLC Distribution Box with a “Step-Start Sequencer” to turn on the screen section-by-section (e.g., every 2 seconds).

7. Why Partner with UnifyLED?

We understand that LED screen installation projects often fail due to a lack of engineering support, not hardware quality.

At UnifyLED, we provide technical backing, not just boxes:

CAD Structural Drawings: We calculate the wind load and frame specs for you.

Power Diagrams: Detailed 3-phase wiring maps to prevent overloads.

On-Site Support: Remote or physical guidance for complex projects.

Ready to engineer your next display?

Contact our Project Team today for a free structural consultation.

8. FAQ - Common Questions About LED Screen Installation

The cost varies by location and complexity. generally, the steel structure materials cost about 10%-15% of the total screen value. For labor, a standard indoor led screen installation might cost 500−500−1,000 per day depending on the crew size, while complex outdoor led screen installation requiring cranes will be higher.

It depends on the type:

Rental Events: With our Fast-Lock system, 2 technicians can finish a 50sqm led screen install in about 2-3 hours.

Fixed Outdoor: Building the heavy steel frame and mounting cabinets usually takes 3-7 days.

UnifyLED is a global manufacturer based in China. While we don't have a physical construction team in every city like Miami or London, we provide the free structural CAD drawings and remote video guidance. Most clients hire a local general contractor to build the frame according to our blueprints.

We do not recommend DIY for large outdoor projects. How to install outdoor led screen structures requires welding certifications and wind-load calculations. However, for small indoor led screen installation (like a shop window), you can easily do it yourself using our user-friendly guidance.

Never underestimate power.

Indoor: Average usage is ~200 Watts/sqm.

Outdoor: Average usage is ~600 Watts/sqm (due to high brightness).

Always consult a licensed electrician to ensure your venue's breaker box can handle the surge current during startup.

9. Recommend

IPS Display vs LED Display: 2026 Ultimate Comparison Guide

Compare IPS display vs LED displays to find the perfect screen for gaming, professional design, or retail. Explore 2026 updates on color accuracy, brightness, and energy efficiency to maximize your ROI.

QLED vs Crystal UHD: Which Display Fits Your Business ROI?

Compare QLED vs Crystal UHD for commercial displays. Learn which technology fits your budget, limits of LCD, and when to upgrade to seamless LED Video Walls.

How to Repair P6 Outdoor LED Display Sign Board Screen

Learning how to repair P6 outdoor LED display sign board screens requires expert knowledge. Discover our step-by-step guide on module replacement, waterproof sealing, and color calibration.