- Home

- »

- LED Display Technology

- »

- LED Screen Cabinet Basics: Materials, Functions & Applications

LED Screen Cabinet Basics: Materials, Functions & Applications

Table of Contents

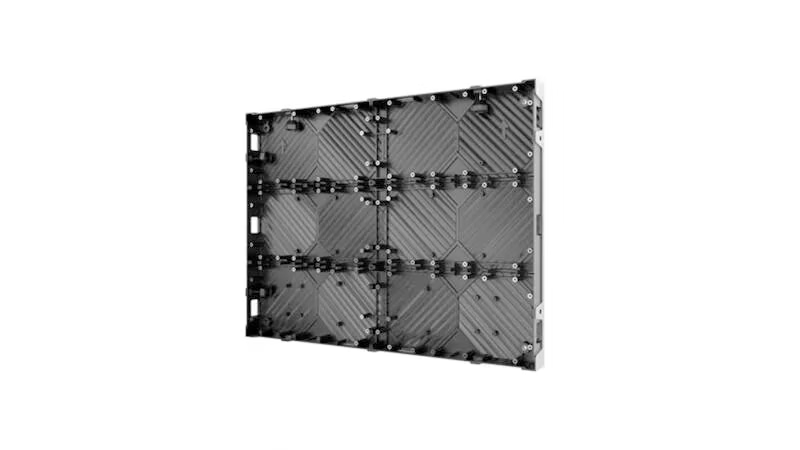

An LED screen cabinet is the core unit of any modular LED display, crucial for protecting components, supporting large screens, and managing heat and power efficiently. Choosing the right cabinet affects installation ease, display stability, and long-term reliability. Across Europe, North America, and Asia, stadiums, outdoor billboards, and rental stages rely on aluminum, magnesium, or carbon fiber cabinets to ensure seamless visuals, durable performance, and simplified maintenance, meeting global technical standards for IP protection and modular installation.

1. What is an LED Screen Cabinet and Its Function?

An LED screen cabinet is the modular unit that forms a complete LED display. Large screens are made of multiple cabinets connected seamlessly. Each cabinet protects internal components, supports structure, enables cooling, and manages power and signal distribution.

Main Components

LED Modules / Panels: Form the display; modular for easy replacement.

Cabinet Frame: Materials include iron, aluminum, magnesium, carbon fiber; affects weight, strength, and durability.

Power & Control System: Ensures stable voltage and accurate signal transmission.

Cabling & Cooling: Hidden wiring improves safety; airflow channels prevent overheating.

Key Functions

Protects internal components from physical damage, dust, and moisture (IP rating: IP54–IP65 for outdoor use).

Provides structural support for large screens, maintaining alignment and stability.

Facilitates heat dissipation to maintain performance (cabinet weight ranges: 9–15 kg per module depending on material).

Simplifies maintenance, especially with modular and front-maintenance designs.

Why It Matters

Lighter, modular cabinets reduce installation effort.

Proper design improves maintenance efficiency and display quality.

Durable cabinets ensure long-term reliability and cost efficiency.

2. LED Screen Cabinet Comparison

When planning an LED display, the cabinet is more than just a frame—it affects installation speed, durability, and long-term performance. Using the wrong cabinet often leads to uneven seams, overheating, or difficult maintenance—problems that only become obvious after setup.

Here’s a detailed comparison to help you pick a modular LED screen cabinet that works smoothly in real-world conditions.

By Material

The material determines weight, structural precision, heat dissipation, and ease of handling, all of which impact daily operation and installation efficiency.

| Material | Weight | Strength | Seam Precision | Heat Dissipation | Use Case | Cost | Advantages / Disadvantages |

|---|---|---|---|---|---|---|---|

| Aluminum | Low | High | High | Good | Rental / Stage | Medium | Lightweight and precise, enables faster and more accurate setup. Medium cost, saves labor, most commonly used for rental and stage screens. |

| Die-Casting LED Screen Cabinet | Low | High | Very High | Excellent | Outdoor / High-End / Rental | High | Highly precise structure, lightweight, durable. Suitable for outdoor and high-frequency transport scenarios. Fast installation and low maintenance. |

| Iron | High | Medium | Medium | Average | Fixed Indoor | Low | Solid and affordable, but heavy and prone to rust. Moving or adjusting panels can be cumbersome, commonly used for fixed indoor screens. |

| Magnesium | Very Low | High | High | Excellent | Outdoor / High-End | High | Strong, weather-resistant, excellent heat dissipation. High cost, ideal for premium outdoor projects, low long-term maintenance. |

| Carbon Fiber | Ultra-Light | High | High | Excellent | Stadiums / Large Screens | High | Extremely light and modular, ideal for large touring screens. High cost, but installation is effortless. Least commonly used. |

Weight and modularity directly affect installation difficulty: lighter materials allow faster assembly, especially for rental and stage screens. Heavy iron cabinets slow down adjustments. Die-casting LED screen cabinets combine light weight, high precision, and durability, making them ideal for high-end and large-scale displays. Looking for lightweight cabinets for easy touring? Our Rental LED Display Series weighs only 7kg per panel – perfect for one-person installation.

By Application

The cabinet choice must match the installation environment, otherwise small inconveniences can quickly become major headaches.

Indoor vs. Outdoor

Indoor cabinets focus on sleek looks and quiet operation. They integrate smoothly into malls or control rooms without heavy lifting.

Outdoor cabinets face rain, dust, and sun exposure. Choosing a material with strong heat management and waterproofing (like magnesium or aluminum) avoids overheating or weather-related failures.

Fixed vs. Rental

Fixed installations favor heavier cabinets that stay put, but they are harder to handle if adjustments are needed.

Rental cabinets prioritize lightweight and modular design, enabling quick assembly, teardown, and transportation—avoiding the frustration of slow setups at multiple venues.

Even within the same material, how a cabinet handles these situations can make the difference between a smooth project and constant troubleshooting.

By Maintenance Design

Maintenance design often goes unnoticed until you need to replace a module. Access type determines how easily repairs are done, affecting downtime and labor cost.

Front Maintenance: Modules are replaced from the front, perfect for wall-mounted or tight spaces. No crawling behind screens or dismantling structures.

Rear Maintenance: Ideal for large outdoor installations, with space for ventilation and power units. Easier for long-term service if back access exists.

Modern modular LED screen cabinets may combine both, letting technicians work efficiently from either side—a huge relief for venues where space is limited or screens are frequently reconfigured.

3. Technical Specifications and Performance Analysis of LED Screen Cabinets

Selecting the right LED screen cabinet is more than just picking a frame—it directly affects installation ease, display stability, maintenance, and overall reliability. The wrong choice can result in uneven seams, overheating, or frequent maintenance headaches, which become painfully obvious whether you’re installing a wall in a European shopping mall, a stadium in North America, or a rooftop billboard in Asia.

Here’s a detailed look at the key technical specifications and how they influence real-world performance.

Weight and Load Capacity

Cabinet weight impacts every stage of a project—from transport to assembly. Heavy iron cabinets are solid, but moving and adjusting them can be slow and labor-intensive, especially for rental or touring setups. Lightweight alternatives like aluminum, magnesium, or carbon fiber allow faster setup, reduce labor costs, and are easier to transport across locations in Europe, North America, or Southeast Asia.

Load capacity also matters. Even lightweight cabinets must support modules, power units, and any additional equipment without bending or warping. Magnesium and carbon fiber strike a strong balance between strength and lightness, which is particularly critical for large stadium installations or outdoor events with high audience visibility.

Seam Precision and Tolerance

Even minor misalignments between LED modules can be highly visible on large displays. Poor seam precision leads to distracting gaps or uneven brightness, diminishing viewer experience. Aluminum, magnesium, and carbon fiber cabinets offer tighter tolerances and seamless alignment, ensuring your display looks polished from any angle.

In regions where visual quality is highly scrutinized—like high-end retail spaces in Europe or corporate installations in North America—choosing materials that guarantee precision avoids costly adjustments during setup.

Heat Dissipation and Protection (IP Rating)

Outdoor screens often face extreme conditions: sunlight in Dubai, rain in London, or humidity in Southeast Asia. Cabinets that dissipate heat effectively prevent LED burnout and maintain consistent brightness. Magnesium and carbon fiber excel in thermal management.

Protection against dust and water is equally critical. High IP-rated cabinets (IP65 or higher) prevent weather-related failures, keeping the display running smoothly for advertising campaigns or sports events without costly downtime.

Modular Installation and Maintenance Convenience

Modularity affects installation speed and maintenance ease, which can be a major concern for rental companies or event organizers who need to move screens frequently. Cabinets with quick-lock assembly systems reduce setup time and avoid alignment frustrations.

Maintenance access is equally important. Front-maintenance designs allow technicians to replace modules quickly from the front—a lifesaver when screens are wall-mounted or in tight indoor spaces. Rear-access designs are better for permanent outdoor installations where back access is available. Some modern cabinets combine both, giving installers flexibility and minimizing downtime.

For example, in North American touring events, front-access modular cabinets save hours per setup. In European stadiums, dual-access designs allow maintenance without shutting down the full display.

Lifespan and Maintenance Cycle

Long-term reliability is a key consideration. Iron cabinets may rust and require frequent maintenance, while aluminum, magnesium, and carbon fiber provide extended durability and reduce maintenance cycles.

Indoor installations: Aluminum or iron works well, balancing cost and durability.

Outdoor installations: Magnesium or carbon fiber ensures the display withstands weather, heat, and UV exposure.

Rental or touring screens: Lightweight modular cabinets reduce labor time and extend component lifespan, especially important for global touring events across varied climates.

Choosing the right cabinet ensures LED display reliability for years while keeping maintenance simple, regardless of geographic location.

4. LED Screen Cabinet Installation & Maintenance Guide

When selecting an LED cabinet, technical specs are only part of the story. How you install and maintain the screen determines long-term performance, reliability, and user satisfaction. Mistakes in this stage—improper mounting, poor cabling, or limited access—can lead to costly downtime or uneven display quality. This chapter builds on the technical insights from Chapter 4 and guides you through practical installation and maintenance strategies suitable for global applications.

Front Maintenance vs Rear Maintenance

Choosing the right maintenance design prevents frustrating delays during repairs:

Front-maintenance cabinets are ideal for wall-mounted or space-limited installations. Technicians can replace modules directly from the front, avoiding the need to access the rear. Without front access, even a minor module failure could halt the entire display for hours. Front-access designs are especially popular in European indoor retail walls and Asian corporate installations, where space is tight and downtime is costly.

Rear-maintenance cabinets require room behind the screen but provide easier access to internal components. They are commonly used in North American stadiums or large outdoor LED displays. While convenient for permanent setups, installing rear-access cabinets in narrow spaces can be tricky, risking misalignment or delayed maintenance.

Suspension and Ground-Mount Methods

The mounting method affects stability, safety, and setup speed:

Ceiling suspension systems are widely used in stage setups, concerts, and temporary events. They allow flexible positioning but require precise load calculations to avoid accidents.

Ground-mounted frames are standard for outdoor advertising, sports arenas, and stadium screens. Proper anchoring prevents vibration or misalignment under wind or uneven terrain. In regions like Middle East deserts or North American stadiums, secure grounding is critical for both safety and image stability.

Signal and Power Cabling: Hidden vs Standard

Cable management may seem minor, but it impacts safety, aesthetics, and long-term reliability:

Hidden wiring improves safety, prevents accidental disconnection, and creates a clean, professional appearance. This is particularly valued in corporate headquarters or indoor malls.

Standard cabling can simplify temporary setups for events, though it may appear messy and require extra attention to prevent wear or damage. In rental applications across Europe or Asia, hidden wiring is often worth the extra effort to minimize troubleshooting.

Modular Disassembly & Maintenance Tips

Efficient modular design ensures quick repairs and minimizes downtime:

Label modules and connectors for easy identification during troubleshooting.

Keep spare LED modules on hand, especially for rental or high-traffic outdoor displays, where downtime can be costly.

Across climates, from humid Southeast Asia to cold European winters, having a clear modular strategy reduces maintenance headaches and ensures consistent display performance.

5. LED Screen Cabinet Applications: Real-World Case Studies

Choosing the right LED screen cabinet is crucial for ensuring long-term reliability, easy installation, and optimal display quality. Different materials and designs are suited for specific applications, whether it’s a stadium, outdoor billboard, or touring stage. Below are common real-world use cases illustrating how cabinet choice impacts performance.

Stadium LED Displays: Magnesium & Carbon Fiber Cabinets

Large stadium screens require high-strength, lightweight cabinets to minimize structural load and allow seamless, high-resolution displays. Magnesium and carbon fiber cabinets provide exceptional rigidity without adding unnecessary weight, making installation faster and reducing strain on supporting structures.

In high-traffic venues across North America, Europe, and Asia, these materials ensure displays remain stable despite crowd vibrations, wind, and temperature fluctuations. The modular design also allows for efficient maintenance, reducing downtime during sports events or concerts.

Heavy or low-strength cabinets can make stadium installations complex, increase safety risks, and complicate maintenance schedules.

Outdoor Advertising LED Screens: Aluminum Cabinets

City billboards and outdoor advertising screens are constantly exposed to weather, sunlight, and temperature variations. Aluminum cabinets are widely used due to their durability, corrosion resistance, and heat dissipation properties.

Ideal for outdoor locations in European city centers, North American highways, and Southeast Asian commercial districts.

They support large panel assemblies while being lightweight enough to simplify installation.

Seamless modular connections prevent visual gaps and maintain brand-impactful image quality.

Cheaper or poorly ventilated cabinets can warp, overheat, or corrode, leading to service interruptions and costly repairs.

Stage Rental LED Screens: Die-Cast Aluminum Cabinets

Touring events, concerts, and temporary exhibitions demand lightweight, modular, and quick-to-assemble cabinets. Die-cast aluminum boxes meet these requirements perfectly:

Quick assembly and disassembly reduce labor costs.

Lightweight design allows transport across multiple venues and countries.

Durable modular connections ensure visual consistency and safe handling during repeated setups.

Heavy, non-modular cabinets increase transport time, risk damage during handling, and slow down event setup.

6. LED Screen Cabinet FAQs

Depends on screen size, pixel pitch, and cabinet dimensions. Miscalculations can cause misaligned seams or wasted space.

Even modular cabinets may develop alignment shifts or loose connections. Regular checks prevent downtime.

Consider material lifespan, maintenance, and labor. Higher upfront cost in durable cabinets often saves long-term time and money.

7. Conclusion

Selecting the right LED screen cabinet is essential for a successful LED display project. By evaluating material, weight, modularity, and application environment, operators can reduce installation challenges, minimize maintenance, and achieve reliable, high-quality visuals. Stadiums in North America and Europe benefit from lightweight carbon fiber or magnesium cabinets, while outdoor advertising screens in Southeast Asia or city centers worldwide rely on durable aluminum cabinets. For rental or touring events, modular LED screen cabinets simplify setup, reduce labor costs, and ensure consistent image quality. Working with a professional LED screen factory ensures the cabinets meet global technical standards, delivering both performance and cost efficiency.

Iron or Aluminum? Indoor or Outdoor?

Stop guessing. Book a Factory Video Call: Let us walk you through our showroom to see the actual build quality of our cabinets closer than ever before.

8. Recommend

IPS Display vs LED Display: 2026 Ultimate Comparison Guide

Compare IPS display vs LED displays to find the perfect screen for gaming, professional design, or retail. Explore 2026 updates on color accuracy, brightness, and energy efficiency to maximize your ROI.

QLED vs Crystal UHD: Which Display Fits Your Business ROI?

Compare QLED vs Crystal UHD for commercial displays. Learn which technology fits your budget, limits of LCD, and when to upgrade to seamless LED Video Walls.

How to Repair P6 Outdoor LED Display Sign Board Screen

Learning how to repair P6 outdoor LED display sign board screens requires expert knowledge. Discover our step-by-step guide on module replacement, waterproof sealing, and color calibration.